- #REPLACING IMPELLER ON INBOARD HOW TO#

- #REPLACING IMPELLER ON INBOARD SERIAL NUMBERS#

- #REPLACING IMPELLER ON INBOARD SERIAL NUMBER#

- #REPLACING IMPELLER ON INBOARD CRACK#

Do not re-use old gaskets and o-rings even if they appear to be in good condition, they can have tiny imperfections that can cause big problems later. We highly recommend you purchase an impeller kit instead of an individual impeller. Get Everything You NeedĪlso, when replacing your impeller, don't forget to use new gaskets and o-rings! Most impellers are available in kits that include all the necessary gaskets and o-rings to properly seal the pump. We recommend using dimensions only as a secondary check once you have used your application information to identify what you believe is the correct impeller. After all, impellers can swell and deform during use, and using the physical dimensions to identify your replacement is not as accurate as using solid application information as described above. How about width and diameter?īy the way, if you are measuring width and diameter of an impeller that has seen a lot of action, be aware that your measurements may not match the factory specifications. Do the number of vanes match? Is the style of shaft the same (keyed, splined, flat sides, etc.). Also, double-check the features of the potential replacement compared to your original. If possible, stick to resources published by the engine or pump manufacturer. There's a lot of good references online, but be careful! Cross-reference information is not always correct, so verify that the impeller described matches the one you are replacing. Once you have the necessary information (part numbers, engine application, model/serial numbers, etc.), you can start searching for the correct impeller replacement. However, if you can read it clearly, then you can quickly find the replacement without much research needed. Many times, the impeller is too worn to read this number it's also pretty small and hard to read. Jabsco and Sherwood impellers usually feature the part numbers in this way. Many impellers may have a part number stamped on the side of the metal hub. If the pump is older, this number may be worn or hard to read, but if you can get it, it will be a valuable piece of information to identify the right impeller for the application. Often, you can locate the part number of the pump on the pump body itself. If you are replacing the impeller in a bronze raw water pump, it may also be helpful to obtain the pump brand and part number. For Johnson/Evinrude, Yamaha, Crusader, PCM, Indmar, OMC and other engines, model numbers are valuable for looking up parts.

#REPLACING IMPELLER ON INBOARD SERIAL NUMBER#

For Mercury, MerCruiser and Volvo Penta engines, the serial number is key. These pieces of information can save a lot of research time and potentially avoid some catastrophic problems.

#REPLACING IMPELLER ON INBOARD SERIAL NUMBERS#

Also, keep the engine model and/or serial numbers handy. Learn the brand of your engine, along with year of manufacture and engine size.

One of the most important steps you can take when replacing your impeller is to know the engine application. While these differences may seem inconsequential, they can actually result in big problems for your engine if you use the wrong one. Many impellers may look similar, but have small, almost-imperceptible differences in dimensions.

#REPLACING IMPELLER ON INBOARD HOW TO#

Knowing how to identify your impeller and identify its replacement can be challenging. However, there are hundreds of impellers of various shapes, sizes and applications available on the market. If you observe that your impeller has sustained significant wear or damage, then you should replace it.

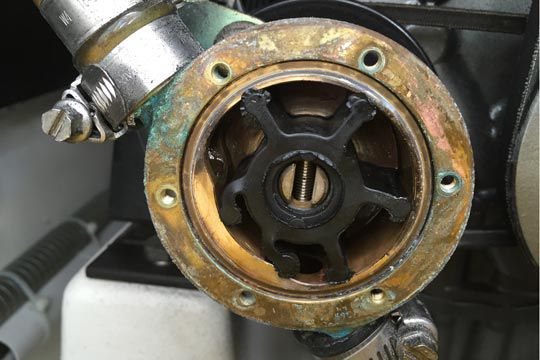

Another possible defect is when the metal hub of the impeller detaches from the rubber, causing a situation where the hub is spinning but the rubber vanes are not turning and not pumping water.

#REPLACING IMPELLER ON INBOARD CRACK#

Additionally, impellers can swell, crack or bend, which can affect the ability of the pump to cool the engine. It is not uncommon for the impeller vanes to tear or break off, causing potential blockage in the cooling system and a loss of water pressure. You should inspect the impeller at least once a year.

Since it is always in use when the engine is running, the impeller suffers a lot of wear and tear. The impeller is a flexible rubber gear that creates the vacuum needed to pump water into your engine for cooling. Whether you are fixing a worn-out inboard engine water pump, rebuilding your stern drive or performing routine maintenance on your outboard motor, you'll likely be replacing an impeller as part of the job. One of the most common items you'll replace on your boat is the water pump impeller.

0 kommentar(er)

0 kommentar(er)